SOLUTIONS

Industrial Solutions

Improve manufacturing with our Industrial Solutions, integrating advanced technologies to enhance efficiency,

reduce costs, and streamline operations for industries like semiconductors, electronics, and renewable energy.

Industry Challenges

High-tech sector, e.g., semiconductor manufacturing is a highly complex and precise process, making it vulnerable to various challenges arising from human errors and lack of know-how.

Impacted production efficiency due to complex processes

The fabrication process includes hundreds of steps, each with numerous variables. Errors in handling, calibrating equipment, or adjusting process parameters can lead to defects. Traditional manual operations leads to uncertainties in the production process and extended production cycles.

Impaired quality control and Yield

Identifying defects at various stages of production is critical. Human error in inspecting wafers or interpreting data can miss defects or falsely identify good chips as defective. Achieving high yields requires minimizing errors However, due to the complexities of the production process, it is difficult to promptly identify and address issues. Mistakes in understanding yield analysis or corrective actions can lead to significant financial losses.

High maintenance costs

Human errors in performing preventive maintenance can lead to equipment failures and production halts. Ineffective response to equipment failures or process anomalies due to lack of expertise can prolong downtime and increase costs.

Our Solution

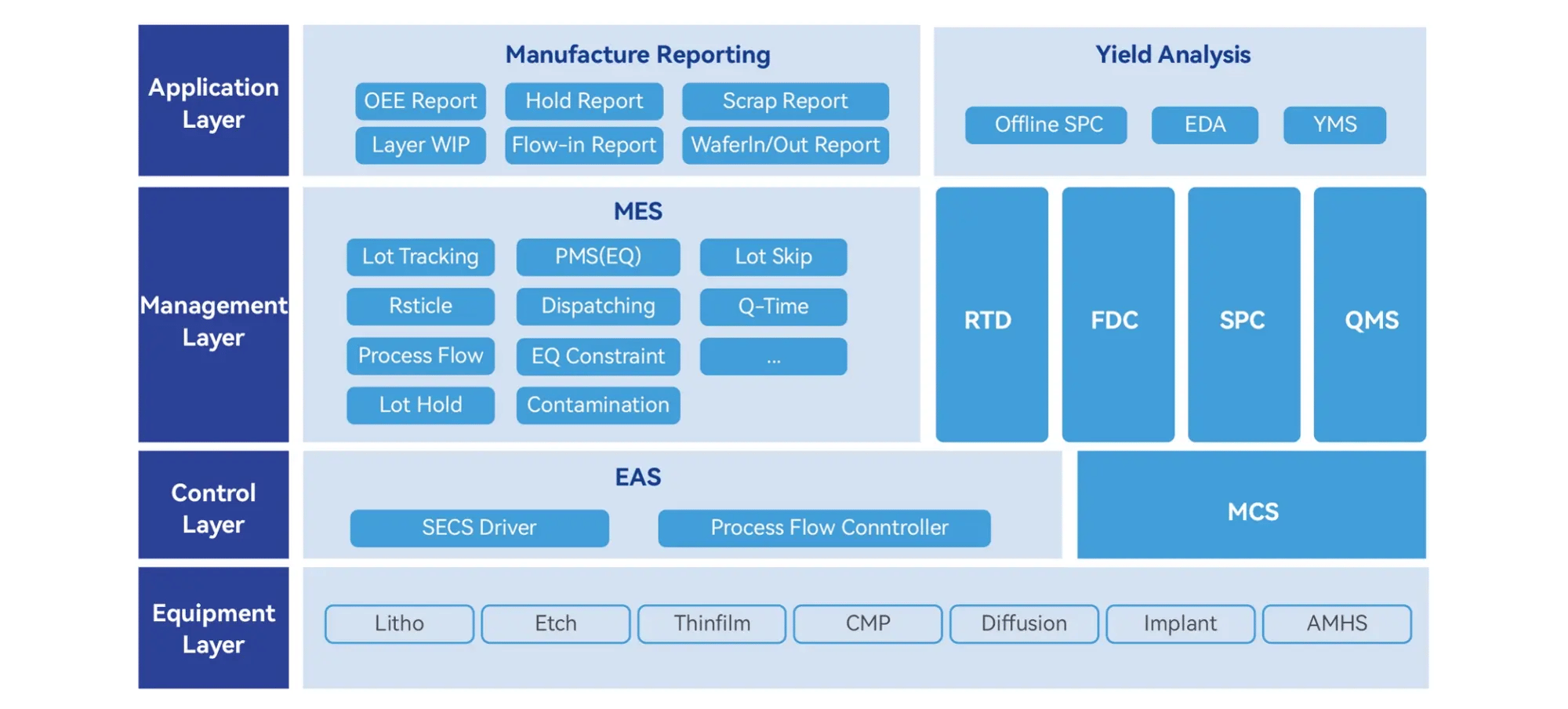

Equipment Automation System (EAS), Real Time Dispatch System (RTD), and Fault Detection and Classification (FDC) are crucial components in the automation and optimization of manufacturing and industrial processes.

● Through Equipment Automation System (EAS), we achieve the automation control and operation of semiconductor manufacturing equipment, thereby improving production efficiency and stability.

● The Real-Time Dispatch (RTD) system monitors production in real-time and enables flexible scheduling, optimizing production plans and resource utilization.

● Utilizing Fault Detection and Classification (FDC) technology, we can promptly detect and classify faults in the production process, reducing production interruptions and product defect rates.

Customer Value

● Higher production efficiency and stability, with shortened production cycles and guaranteed delivery times

● Effective quality control ensures reduced product defect rates

● Reduced labor and equipment maintenance costs

● Therefore, our solution not only addresses the challenges faced by semiconductor factories but also creates sustained value for customers.

Related Solutions

Real Time Dispatch (RTD)

Boost operational efficiency with Real-Time Dispatch (RTD), enabling precise scheduling, dynamic resource allocation, and real-time monitoring to minimize delays and optimize productivity across high-tech industries.

Get Inquiry Now

Reach out to us for tailored solutions to your business needs. Share your inquiries, and our experts will provide personalized guidance to help you achieve your goals efficiently.

.png?width=188&height=55&name=image%20(2).png)

.webp)

.webp)